President Serdar Berdimuhamedov led Wednesday (20 Jul) the opening ceremony of the Center for Repair and Maintenance of Power Equipment. It is the unique facility on a scale of Central Asian region.

Addressing the participants of the ceremony, the head of state noted: “In our country, great attention is paid to the development of the energy industry and the building up the industry’s material and technical support. In recent years, a number of new modern power plants have been built in all provinces. Currently, a number of major projects are underway in this sector. The construction of the country’s internal energy ring and the Turkmenistan–Afghanistan–Pakistan power transmission line continues.”

The center is designed to repair the essential equipment of energy facilities, thus reducing the time and costs for these services. The Center will also contribute to the training of highly qualified staff of the relevant profile, the head of state noted.

The project has been fulfilled by the Turkish company “Çalik Enerji”. The facility has created over 120 new jobs.

With the commissioning of the repair center, since now there is no need to send turbine parts for repair abroad. For the modernization of turbines, the company has installed General Electric technologies, which is cost- and fuel consumption effective. This advanced solution also makes it possible to extend the service life of the equipment.

Technical features of the Center

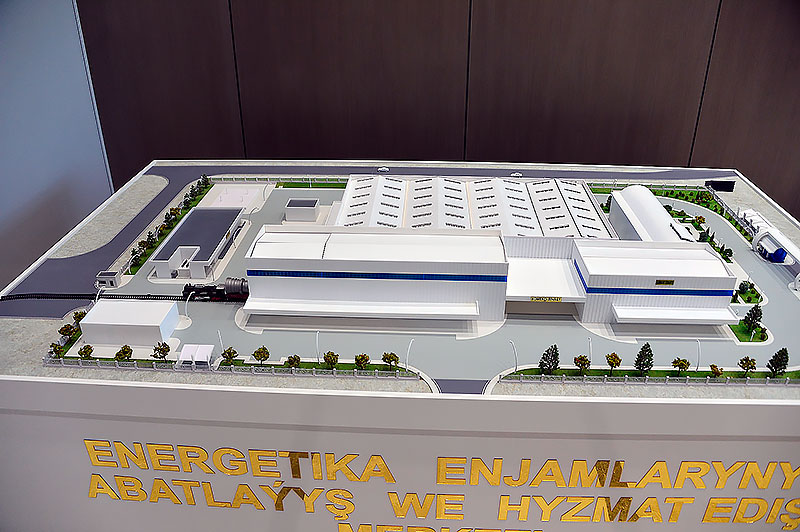

The Center for repair and maintenance of power equipment is located on an area of 3 hectares in Buzmeyin district of Ashgabat. 55 units of specialized equipment have been installed there.

The complex accommodates specialized workshops, a laboratory, an administrative building, a conference hall, an archive, a warehouse, technical, utility rooms and other necessary premises.

The specialists of the Center have undergone foreign professional training, as well as online training in cooperation with General Electric.

In the repair shop, a 5D image was demonstrated using the example of one of the modifications of General Electric gas turbines. The turbine repair process includes preliminary cleaning and diagnostics of devices, elimination of mechanical defects, welding, application of heat-resistant and cold-resistant coating, hardening of parts in a vacuum furnace, etc. After the repair of the equipment is completed, it is tested.

The center is equipped with advanced specialized equipment, including those designed for testing, checking and cleaning gas turbine parts in various ways. There is also a welding cabin with a hood and filters, through which the gaseous and smoke emissions generated during welding are removed. A metal chip aspiration system is installed in the cabin for machining parts.

The coordinate measuring machine and the three-position machining tool operate on the basis of digital technologies.

With the help of a borescope, inside inspection and diagnostics of gas turbine parts through a 4-mm video camera are conducted without disassembling them.

A software-controlled tensile test bench is used to determine the physical characteristics of metals.

There are also systems for detecting invisible defects of the repaired equipment using the method of spraying a special indicator substance – fluorescent or red penetrant.

An industrial robot from FANUC Robotics Europe S.A., one of the world’s leading companies in the field of production automation, is designed for the relevant types of work.

A vacuum furnace is installed in the Center, designed for quenching the repaired parts of gas turbines by pre- and after-welding heat treatment, as well as for restoring the crystal lattice of the metal. Another specialized furnace is designed for heat treatment of the working blades of gas turbines. There are also other specialized devices and tools.

The president gifted to the Center new cars.

Service center awarded foreign certificates

During the opening ceremony, a number of certificates were awarded to the new Center:

- Certificate of permission to use the technologies of General Electric (USA) in the Center for repair and maintenance of power equipment.

- Certificate of the British company “The London Energy Club” as the only service center of this profile in Central Asia, as well as an advanced project and engineering complex.

- Certificate for the introduction of sustainable and advanced technologies from the Fraunhofer Institute of Energy Economics and Technology of Energy Systems (Germany)

- Certificate confirming that the facility is built at a high quality level – granted by the branch of the company “TUV” (Germany) in Austria

- Certificate of environmental friendliness – granted by the University of Duisburg-Essen (Germany)

///nCa, 21 July 2022, (photo source – TDH, Turkmen TV screenshots)