nCa Analysis

“Do not waste water, even if you are on a running river.” – Hadith of Holy Prophet (PBUH)

“A drop of water, a grain of gold.” – Turkmen proverb

The Taliban in Afghanistan is building an enormous canal to draw water from the Amudarya. It is their right to consume water from the shared resources but the sheer size of the canal – 100 meters in width – raises alarm, not just for the other countries sharing this river but more so for Afghanistan.

According to the media reports, there are no plans for lining the canal. This is hazardous.

An unlined canal of this size would cause enormous waste of water and would be dangerous for many other reasons:

Water Loss Through Seepage – The single biggest problem caused by unlined irrigation and drainage canals is water loss due to seepage. All soils are somewhat porous due to the gaps between individual soil particles. These spaces allow water to flow out and away.

Unlined canals can lose up to 50% or more of their water supply [in some cases, 60-80%] to seeping alone. This is due to the porosity of even the most clay-heavy soils and was determined by studies done by the U.S. Bureau of Reclamation.

Seepage also creates many secondary negative effects. It’s a contributing factor to soil damage through anaerobic conditions, loss of stability that triggers collapses or landslides, and root rot of nearby plants if the soil doesn’t get to ever dry out.

Soil Stability and Water Saturation – Another major secondary problem, caused by water seepage, is saturation of surrounding ground.

Low Water Velocity – The unlined earthen canal suffers from the lack of water velocity. It is a paradoxical situation – if you raise the speed of water to more than 0.7 meters per second by sloping the bed, there would be erosion in the canal.

Weed Growth In and Around Canals – In an unlined canal, there would be the growth of different aquatic and semi-aquativ weeds. This would slow the velocity of water and, over a period of time, would clog the canal.

Siltation Blockages – Unlined canals high level of silt. It is an expensive and time-consuming process to desilt a canal.

https://www.btlliners.com/issues-common-to-unlined-canals

* * *

Canal lining is a layer of impermeable material installed on the bed and sides of a canal to enhance its lifespan and discharge capacity. Constructing canal lining can help to save up to 60 to 80% of water that would otherwise be lost due to seepage in an unlined canal.

Canal lining is the process of providing a protective layer to the sides and bed of a canal to prevent water seepage and erosion. This lining, often made of concrete, clay, or synthetic materials, not only conserves water but also improves flow efficiency and reduces maintenance costs, ensuring the long-term sustainability of irrigation systems.

https://testbook.com/civil-engineering/canal-lining

* * *

The lining can be made using various materials such as cement, concrete, plastics, boulders, bricks, etc. The main objective of canal liners is to protect the water from seepage loss. Using a canal liner can reduce water loss through seepage by up to 60% to 80% as compared to an unlined canal.

Essentially, there are two types of canal linings:

Earthen type canal liner – are of two types:

- Compacted earth lining: This canal liner is recommended to be made in canals that have earth in close vicinity. In that case, it is a cost-effective and efficient option.

- Cement earth lining: Made by mixing sandy soil, cement and water, which hardens to a concrete-like material, cement earth lining is great for erosion protection and providing strength for large channels.

Hard surface canal liner – are of three types:

- Cement concrete lining: One of the most widely used canal liners, the cement concrete lining is tough, long-lasting, impermeable. It can be used for small or large channels.

- Brick lining: As the name suggests, brick lining is made by lining bricks and smoothening the top and sides with cement mortar.

- Plastic lining: A relatively newer type of canal liner, plastic canal liner can be made using polyvinyl chloride, high molecular high density polyethene and low density polythene. It is a promising alternative to cement/earth liner. HDPE canal liner, a variety of plastic canal liners, is a great technology as it allows for large applications that require UV and ozone resistance, chemical resistance, and high-quality installations.

Canal Liners are an affordable solution to prevent water loss due to seepage. It has been estimated that irrigation canals experience water loss of 30-40%, with seepage being one of the main factors causing water loss.

Western Environmental Liner, Arizona (A wholly owned subsidiary of Western Ag Enterprises Inc.)

https://westernliner.com/liner-applications/canals/

* * *

Turkmenistan has the capacity for the production and use of the canal lining materials.

We are reproducing here a report from UNDP Turkmenistan, published in October 2021. We also published this report at our website simultaneously in 2021.

The production of two types of сanal lining materials is established by the efforts of the UNDP

Shohrat Niyazmuradov, UNDP Project Manager

The need to reduce water losses due to canal infiltration and associated land salinization is common throughout the country, at all levels of the water management system, from long distribution lines to individual farms. But the cost and effort required for lining over 40,000 km of supply and drainage canals is enormous.

In accordance with the second component of the joint UNDP/GEF project “Energy efficiency and renewable energy for sustainable management of water resources of Turkmenistan” that presupposes increased investment in improvement of water infrastructure in order to reduce water losses, save energy and reduce land degradation, it was decided to focus on demonstration, testing with the subsequent introduction of production processes necessary for manufacturing canal lining materials using local raw materials.

The greatest potential for the project in terms of speedy, reasonable and large-scale outcomes on canal lining is with the domestic production that has untapped opportunities for upgrading materials, productivity as well as efficiency gains.

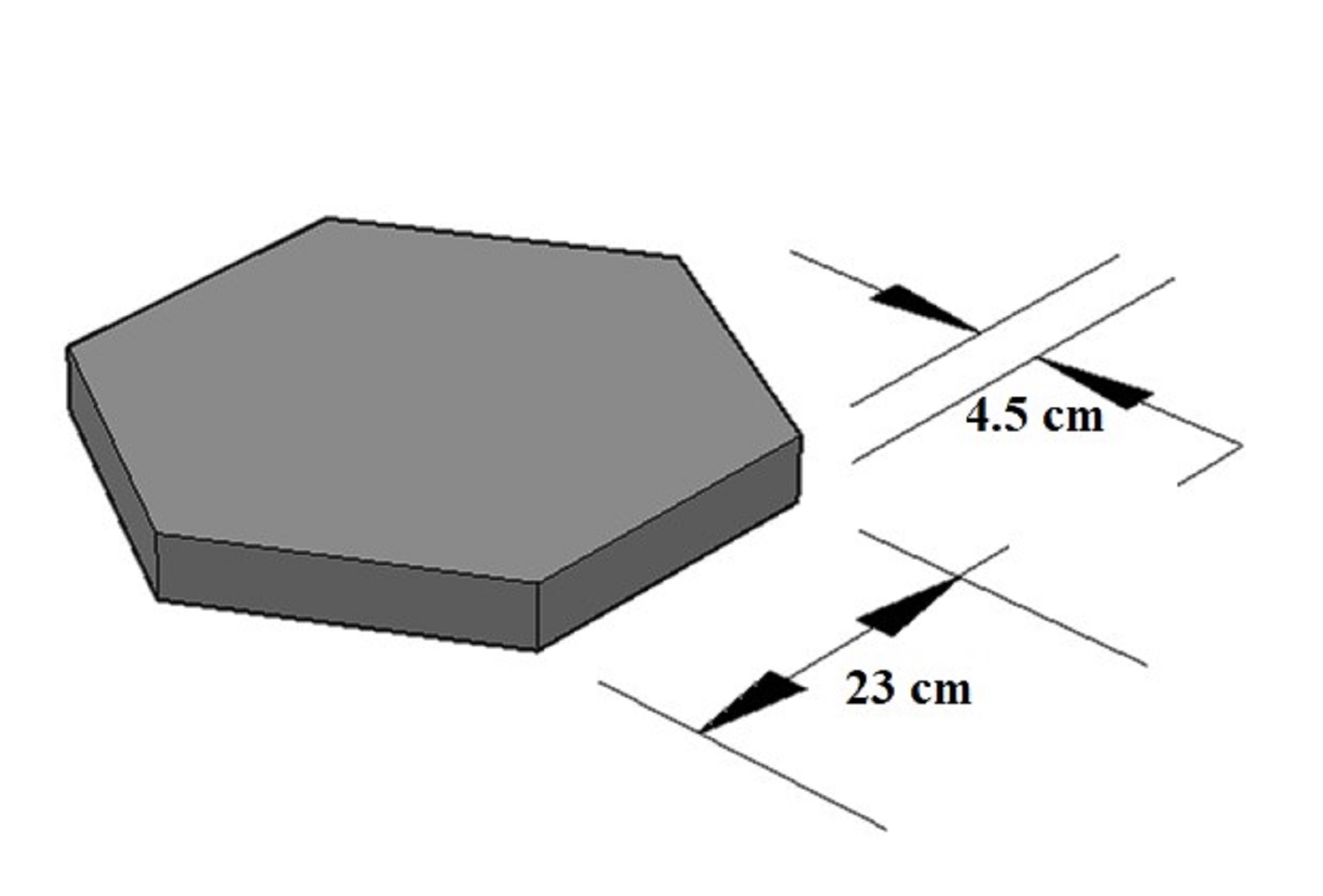

The main project partner, the State Committee for Water Economy of Turkmenistan, currently operates a plant in Bezmein, which produces mainly reinforced concrete pipes and canal slabs. UNDP and the State Committee for Water Economy of Turkmenistan (SCWET) have identified a priority area where production at the plant can be efficiently expanded, redirected and made more efficient and cost effective. One lining option that has been empirically tested is the lining of the canal with a 0.5 mm high density polyethylene (HDPE) membrane protected by a 5 cm layer of sand and a layer of hexagonal concrete slabs. The main function of an intermediate sand layer is to protect the membrane from being punctured by hexagonal plates during installation. The advantage of this option is the lower consumption of raw material in the production of the HDPE membrane, and that it can be produced locally in a short time.

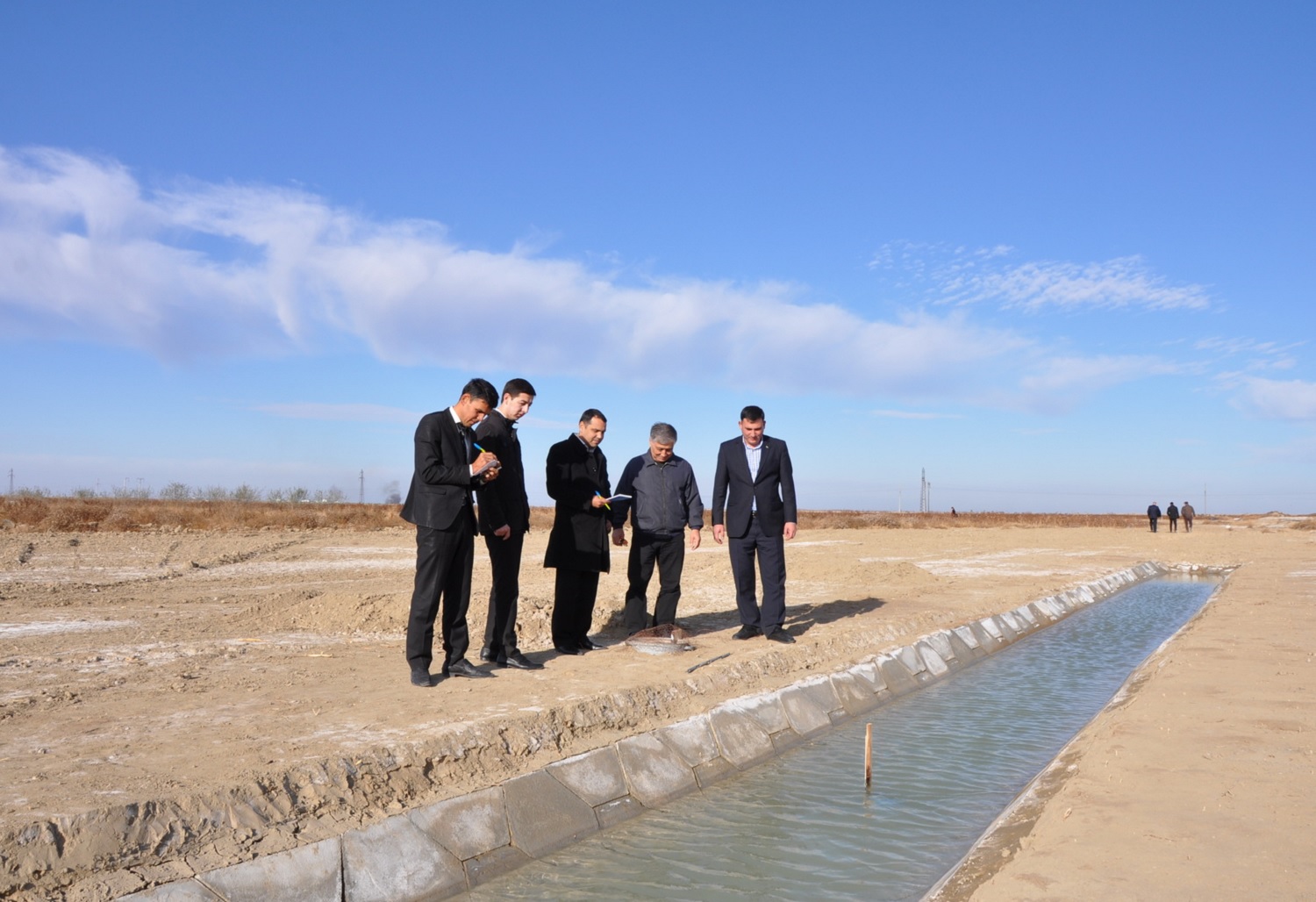

On the research site of 145 hectares, a demonstration section of a canal in an earthen bed had been lined by means of covering with an anti-seepage polyethylene film and hexagonal concrete slabs.

|

|

| Figure 1 The design of hexagonal slabs | Figure 2 Lining of the irrigation canal with a film with a protective layer of hexagonal slabs | |||

|

|

|||

| Figures 3-4 Finished irrigation canal, lined with polyethylene film with a protective layer of hexagonal slabs | ||||

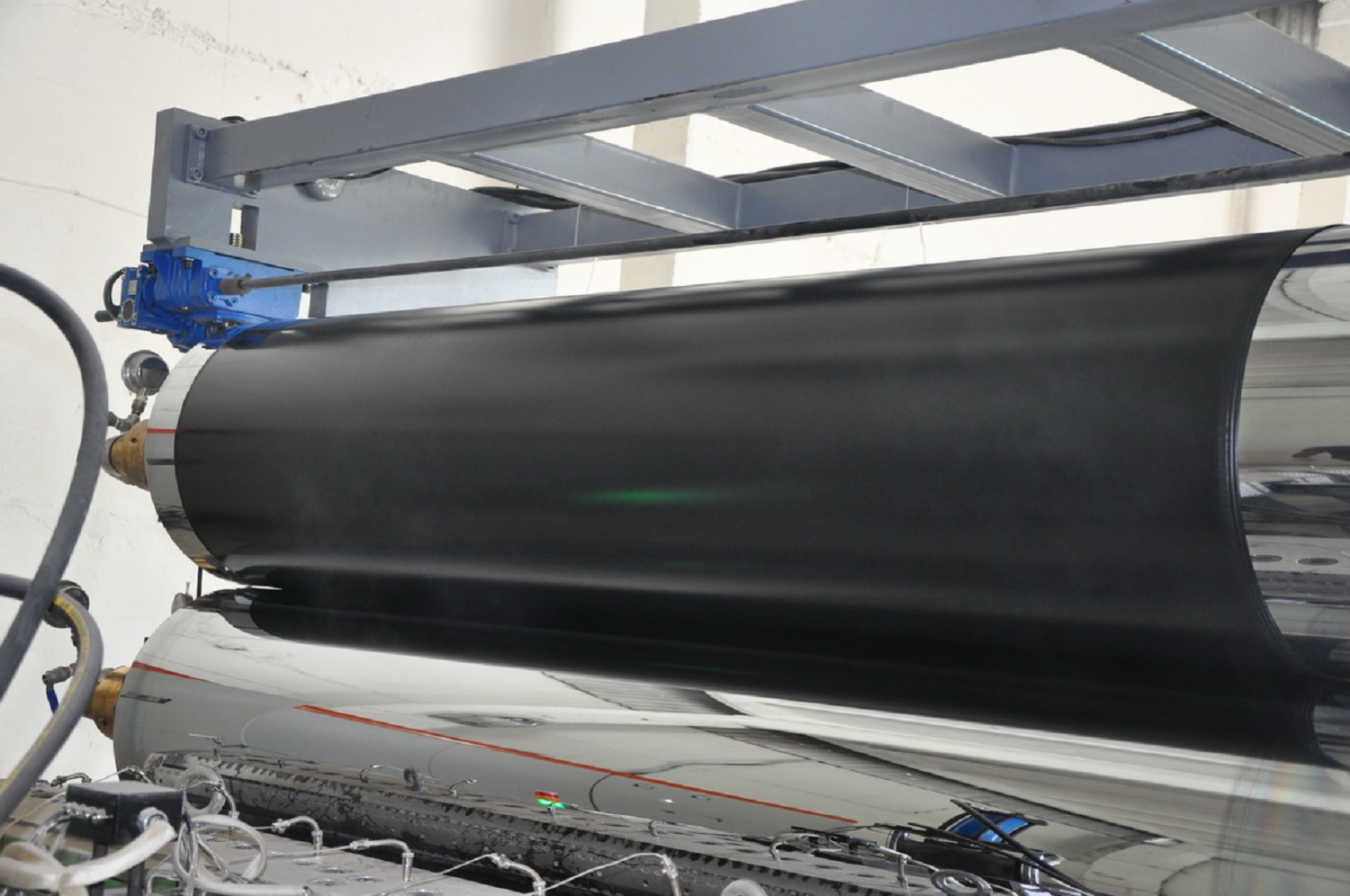

1. Extrusion Line to produce High-Density Polyethylene (HDPE) geomembrane

As part of the project, UNDP purchased and installed an extrusion line to produce HDPE membrane at the Bezmein enterprise of construction products of PA Ahalsuwhojalyk of the State Committee for Water Economy. After delivery and installation of the necessary equipment, the Supplier conducted a three-day training for the operators and maintenance personnel of the end-user on the operation, diagnostics, maintenance and minor repairs of the extrusion line and on the production of high-density polyethylene film. During the training, the operation of the equipment was demonstrated, including the production of a trial batch of a polyethylene membrane in the amount of 500 kg. Also, within the framework of the release of a trial batch of products as a part of commissioning process, the best type of local raw materials for the production of geomembranes was determined through testing.

Figures 5-6 Extrusion line for the production of impervious polymer coatings installed at the SCWE plant for the production of construction materials in Bezmein

In addition to the production line, laboratory equipment for measuring and controlling the quality of products has been supplied, as well as welding equipment for gluing finished polyethylene film into large assembly rolls (depending on the size of the channels).

Furthermore, a granulator is installed for processing waste residues. This device can produce polypropylene granules from its own production residues, as well as from secondary raw materials. Using this device allows enjoying the environmental and economic benefits of plastic waste disposal.

In addition, the Supplier provided two copies of the operating instructions of the extrusion line in Russian.

Recently, the title for the asset has been transferred officially to the end user. During an upcoming operation of the equipment by the end user, raw materials to produce HDPE membranes will be purchased from a polymer plant located in Kiyanly (Balkan region), commissioned in October 2018.

Technical parameters of the HDPE membrane:

1. Raw material to be used: granular polyethylene (HDPE – LDPE) or similar recycled materials;

2. Productivity: 100 – 200 kg/h;

3. Size of the product (membrane): width from 2000 mm, thickness 0.5mm +/- 10%.

Summing up, it is worth noting the fact that within 15 years of operation lifetime, the equipment will be able to produce a quantity of HDPE film to allow lining 1950 km. of canals and is expected to lead to energy savings of 80,940.6 GJ. and a reduction in greenhouse gas emissions of 13,899 tCO2.

2. Forms for casting hexagonal concrete slabs

To date, within the framework of the project, 1200 pieces of rubber precast hexagonal slabs – used in the manufacture of hexagonal concrete slabs to protect the polyethylene film from mechanical damage when lining irrigation canals with an anti-filtration coating – have also been purchased and transferred to the Buzmein plant of construction materials. It is worth noting that with this number of precast hexagonal slabs, it is estimated that approximately 250 m2 of finished concrete slabs can be produced during one working day (8 hours).

A comparative analysis of monitoring water losses from a canal section lined with an anti-seepage coating in a natural earthen bed on medium loamy soils showed that hourly water losses in a lined canal account to 4 litres, which provides a canal efficiency of 0.99 (losses occur mainly due to evaporation with water surface), and in the earthen bed channel the hourly water loss is 205 litres.

Theoretically, reducing water losses from canals and improving drainage in irrigated areas can bring the following benefits:

• Increasing irrigated area due to the saved volumes of water;

• Reducing the volume of removed drainage;

• Lowering groundwater levels and improving conditions for growing crops and increasing yields.

This report was also published by nCa at this link:

* * *

It is important for Afghanistan to understand that the canal they have started building to draw the water from the Amudarya, cannot be viewed in isolation. Central Asia follows a holistic approach – everything is connected with everything else.

If the work continues on the construction of the canal unilaterally, it would quite likely impact negatively the many and various initiatives currently in motion between Central Asia and Afghanistan. /// nCa, 12 March 2024