Serdar Nuryagdiyev, the Chief Geologist of the State Corporation Turkmengeology of Turkmenistan gave a presentation on Carbon Dioxide Gas and Sulfur in the Production of Hydrocarbon Resources during the TESC 2024 in Ashgabat.

The presentation was technical in nature, meant for the industry professionals. However, we are producing a reformatted version of it here to underline the concern for ecological safety and sense of responsibility shown by Turkmenistan in its hydrocarbon activities.

Ladies and gentlemen! Dear participants of the International Scientific Conference

To reduce the long-term consequences of global warming, the technology of capturing, transporting and recycling and (or) burying carbon dioxide is considered as one of the key technologies.

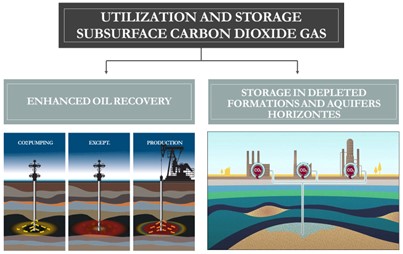

Currently the most studied options recycling and storage carbon dioxide in the subsoil are: the use of carbon dioxide as an agent in enhanced oil recovery methods, CO 2 storage in layers of depleted hydrocarbon deposits and in mineralized aquifers.

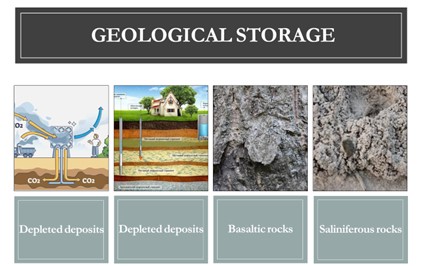

Geological storage involves injection of CO 2 into rock layers that are capable of its absorption and long-term safe retention. Suitable breeds for these purposes are found in sedimentary basins distributed throughout the globe. Directly to as natural stores of carbon dioxide in in the subsoil we can consider rock layers of worked-out deposits of hydrocarbon raw materials, highly mineralized aquifers, and also basalt and salt-bearing rocks.

Most successful considered application of captured carbon dioxide is as an agent for increasing oil recovery. In general, the areas of application of carbon dioxide are quite extensive and, they can be divided into 3 main areas:

– chemical use (areas of application – production of chemicals, fertilizers, food and etc.);

– “mineralization” (production of building materials and etc.);

– biological use (stimulation of plant growth).

Based on CO 2 retention, there are four main mechanisms in the depths:

1. Structural retention caused by the presence of a geological trap. Carbon dioxide pumped into trap reservoir remains motionless and physically not capable of migrating beyond its boundaries due to the presence of an impenetrable barrier (tire rock, shielding fault and etc.).

2. Hydrodynamic retention due to capillary forces in pore space of the reservoir rock.

3. Retention by dissolving CO 2 in formation waters, as a result of which the aggressive properties of the injected gas are neutralized.

4. Mineral retention through chemical interaction with host rocks and vibes with the formation of a solid precipitate or aqueous solutions. As a result, carbon dioxide is completely converted and ceases to exist in its original composition.

To geological conditions and The characteristics of carbon dioxide storage tanks must have special requirements to ensure long-term safe storage of CO 2. Leaks of carbon dioxide must be excluded, to ensure the safety of underground sources of drinking water supply, and also its outcrops to the surface. Therefore, the potential geological sites for carbon dioxide disposal should be assessed according to the following basic criteria:

– compliance of the potential rock formation under consideration with the conditions of long-term retention and non-release of injected carbon dioxide;

– the degree of influence of acidic components on the rocks in question and the fluids saturating them with to protect mineral resources and formation water.

As the main options for carbon dioxide storage, we can consider layers of depleted hydrocarbon deposits and mineralized aquifers.

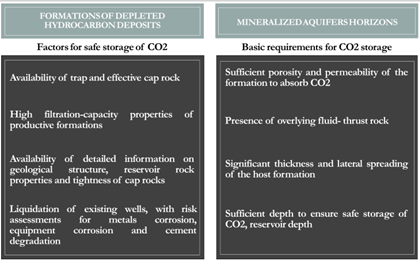

Productive strata of depleted hydrocarbon deposits can be considered as favorable objects for long-term safe storage of CO 2 due to a number of factors. Firstly, the presence of a trap and, in particular, an effective cover rock that contributed to the preservation of deposits in the course of geological periods. Secondly, the high filtration and capacitive properties of productive formations, which ensured natural accumulation and hydrocarbon storage, and their subsequent extraction.

They will allow efficient injection of carbon dioxide into plast. The third aspect is that in during exploration and development of hydrocarbon deposits, a significant amount of detailed information is accumulated about geological structure, properties of reservoir rocks and seal rock tightness. This significantly reduces the uncertainty in the behavior of the injected CO 2 layer.

Together with this, the injection of aggressive carbon dioxide into layers of depleted oil fields and gas poses the task of abandoning existing wells, assessing the risk of metal corrosion and degradation of cement, equipment with subsequent possible leaks.

Aquifers can be considered as objects for storing CO 2 if they meet the following basic requirements: porosity sufficient to absorb carbon dioxide and formation permeability; the presence of fluid-resistant rock overlying the aquifer that can prevent the dispersion of carbon dioxide; significant power and lateral extension of the host reservoir to store large volumes of CO 2; formation depth sufficient to ensure safe storage (more than 800 m – at such depths, in conditions of elevated thermobaric conditions, carbon dioxide goes into liquid or supercritical state with relatively high density).

Some of the limiting factors for the development of this carbon dioxide storage option are the need for additional detailed geological studies of potential storage sites.

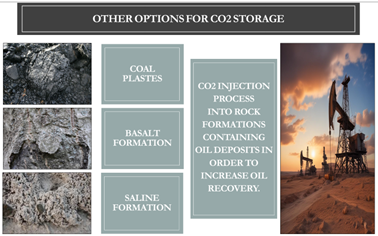

In addition to these main options, carbon dioxide storage can also be carried out in undeveloped coal seams, salt-bearing and basalt formations.

CO 2 injection process in rock layers containing oil deposits, with the aim of increasing oil recovery. A large share of all existing projects using enhanced oil recovery methods in world – This is the injection of carbon dioxide. Moreover, upon completion of the facility’s operation, almost all of the injected carbon dioxide remains in layer.

The part of the injected CO 2 that breaks into production well along with oil, separated from it, compressed and then downloaded again plast. This cycling minimizes carbon dioxide leaks during oil production.

It should be noted that not all oil fields are suitable for the application of enhanced oil recovery techniques with using carbon dioxide. It depends on the properties of the reservoir rocks and saturating them with oil. /// nCa, 10 June 2024