Oraznazar Kheshdekov

The Shatlyk (East and West) gas condensate field, the largest of its kind in Central Asia, began operation in 1973.

Initially, a project aimed to increase well production capacity by using larger diameter drilling bits (216 mm) and well casings (177 mm). This approach also involved replacing traditional 148 mm or 168 mm casings with wider 177 mm ones, along with thicker pumping and compressor pipes (127 mm). However, this metal-intensive design proved impractical as such large diameter pipes weren’t readily available in the USSR at the time.

To find a solution, a test well was drilled at the Tejen gas condensate field. This well reached a depth of 5,000 meters and utilized a 216 mm bit for initial drilling. While a 177 mm casing was initially installed, it was later replaced with a standard 168 mm casing. Additionally, 114 mm diameter pumping and compressor pipes were used.

This experiment successfully demonstrated that replacing a 168 mm casing with a 177 mm one, without altering the drilling bit size, didn’t affect gas well output. This approach, validated through theory and experimentation, was then adopted for all production wells drilled at the Shatlyk field.

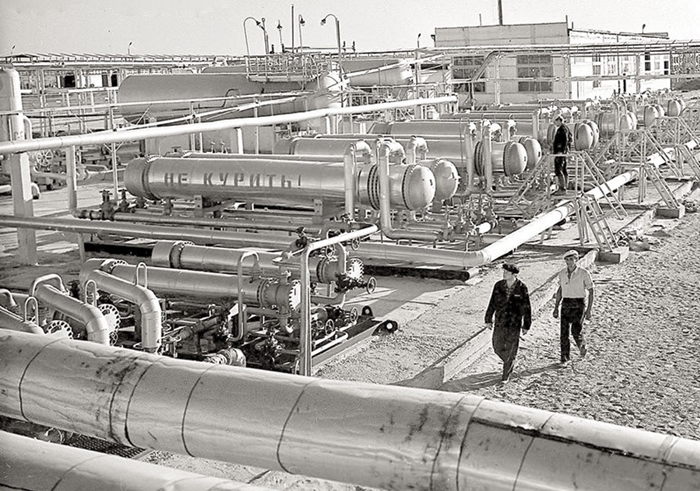

Shatlyk gas condensate field, 1975. Photo credit – K.Hallyyev.

In addition, for the first time in the former USSR, the Shatlyk gas condensate field has begun to partially build integrated gas treatment plants (GTP). Each of them consisted of 5 production lines, to which 5-6 production wells were connected. The lines were equipped with separator – heat exchange equipment, thus, 1.0 billion cubic meters of natural gas per year were produced on each of the lines, in total 5 billion cubic meters of natural gas supplied to consumers from each of the plants.

Eight gas treatment plants were built at the Shatlyk gas condensate field, and their total annual gas production capacity was brought to 40 billion cubic meters. The USSR State Prize in Science and Technology was awarded to the most distinguished Turkmen gas workers for the material and technical benefits from the integrated development of gas fields.

For services to the discovery of the unique Shatlyk gas field, conducting effective exploration and accelerated preparatory work for the development of deposits in the desert conditions of the Karakum in 1974, a group of oil scientists, gas engineers and geologists including B.Atdaev, M.Ashyrmammedov, V.V.Denisevich, V.Y.Sokolov, I.V.Vasilyev, G.N.Kalmykov, B.V. Semenovich, D.N.Milshtein, G.N.Amursky were awarded the title of laureate of the USSR State Prize.

In 1975, a large group of workers, engineers and employees who distinguished themselves during the construction and operation of the facilities of the first stage of the Shatlyk gas condensate field and the Shatlyk – Khiva main gas pipeline were awarded orders and medals.

Gas extracted from production wells underwent deep processing before being delivered to consumers through pipelines. During the initial phase, when natural gas pressure is high enough, a process called low-temperature separation was used. This technique leverages the natural pressure of the gas to remove impurities and moisture through a cooling process. The purified gas is then suitable for delivery to consumers. Additionally, heavier hydrocarbon components were separated and condensed into a liquid form, known as gas condensate, which was sent to refineries for further processing.

At the second stage, as the pressure in the gas field declines over time, the initial low-temperature separation method becomes less effective. At this stage, artificial cooling devices take over to remove remaining liquids, primarily moisture and gas condensate, from the natural gas stream. This ensures consistent gas quality for consumers even when natural pressure diminishes.

Let’s look at the data describing the annual increase in gas production in the country in 1966-1976 (the year of the creation of the production association “Turkmengazsenagat” (Turkmen gas industry): 1966 – 51 million cu m; 1967 — 926 million cu m; 1968 — 3.536 billion cu m; 1969 — 6.426 billion cu m; 1970 — 11.234 billion cu m; 1971 — 15.833 billion cu m; 1972 — 22.712 billion cu m; 1973 — 27.139 billion cu m; 1974 — 37.169 billion cu m; 1975 — 46.856 billion cu m; 1976 – 55.507 billion cu m (Note: the figures are given from the information provided in the annual statistics of that period)

Implementing accelerated production methods led to a staggering 109-fold increase in gas output by the “Turkmengazsenagat” production association within just a decade. This remarkable achievement stemmed from the association’s strong foundation at its inception. As a result, Turkmenistan gained international recognition not only for its oil, carpets, and Akhal-Teke horses but also for becoming the second-largest gas producer in the former USSR. ///originally published by the newspaper “Nebit-Gaz”, 14 June 2024 (https://oilgas.gov.tm/ru/posts/news/11150/istoriya-razvitiya-gazovoy-otrasli-turkmenistana )