In just six years, “Turkmen Senagat” has become the undisputed leader in Turkmenistan’s polyethylene pipe industry. The company’s facilities are located within the Anau industrial zone, the administrative center of the Akhal province.

In just six years, “Turkmen Senagat” has become the undisputed leader in Turkmenistan’s polyethylene pipe industry. The company’s facilities are located within the Anau industrial zone, the administrative center of the Akhal province.

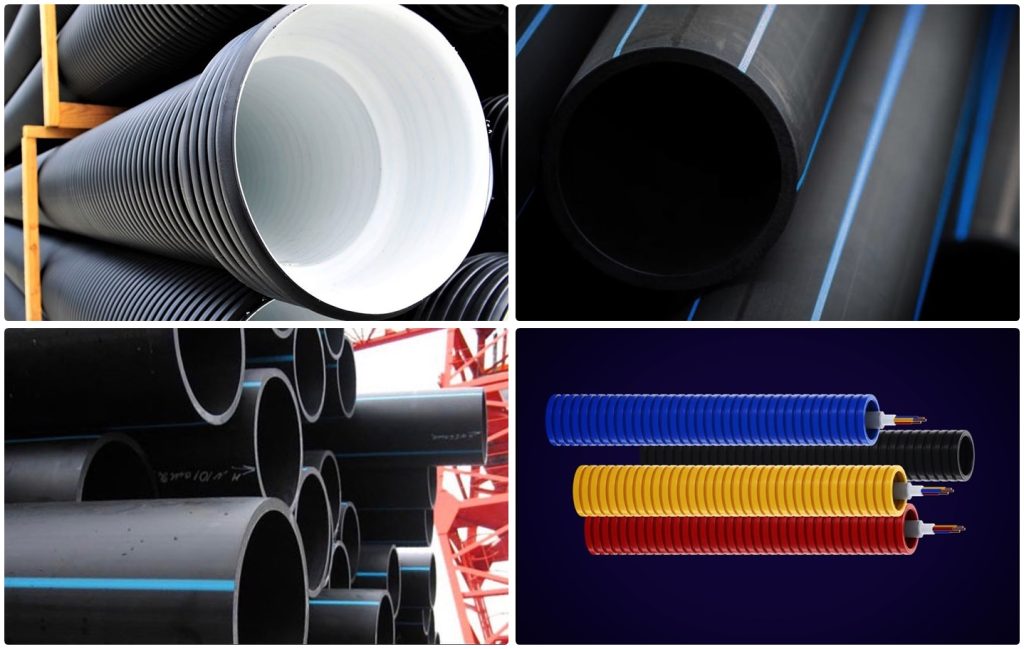

Having a daily production capacity exceeding 250 tons, their state-of-the-art plants churn out a diverse range of polyethylene pipes. This includes smooth pipes for water and natural gas transportation, corrugated pipes ideal for drainage and sewerage systems, and pipes specifically designed for drip irrigation applications.

The production complex encompasses a massive 8,000 square meters, with an additional 10,000 square meters dedicated to efficient storage solutions.

Notably, “Turkmen Senagat” prioritizes using domestically produced polyethylene. The raw materials arrive in the form of pellets, delivered directly from the Kiyanly Polymer Plant, located in the Balkan province.

Türkmen Senagat caters entirely to Turkmenistan’s domestic demand for pipes across various diameters. Their commitment to innovation recently led to the installation of new production lines. These advanced lines enable the company to manufacture the entire spectrum of pipe products, ranging from a compact 16mm to a substantial 1200mm in diameter.

The high-quality raw materials, sourced from the Balkan province, contribute to the exceptional durability of their pipes. This translates to a remarkable lifespan of up to fifty years, allowing them to confidently compete with international counterparts. An additional advantage is the pipes’ impressive resilience – they can elongate nearly fivefold in case of landslides.

Türkmen Senagat exports their products to Türkiye, Kazakhstan, Uzbekistan, Azerbaijan, and Georgia.

Pipes from Turkmenistan are in great demand in Kazakhstan. In the near future, another batch of Turkmen products will be sent there, which is resistant to the Kazakh cold, as well as applicable in a variety of fields. This includes municipal, agricultural, and marine sectors, as well as fish farms, wastewater systems, drainage solutions, and even fire safety pipelines.

Jalai Jalaev, Assistant Director of Türkmen Senagat, told about the prospects for further work of the company: “Work is currently underway on the installation of modern equipment for the production of double-layer corrugated pipes with diameters from 315 to 800 mm. Among other development areas is the strengthening of production capacities, which is associated not only with an increase in orders from Central Asian countries, but also from the local construction companies.”

The representative of the company also highlighted the growing competition in the domestic market of the country, which is associated with the emergence of new manufacturers.

The company is currently working on several relevant projects in the field of downpipes and agriculture. In this regard, Turkmen Senagat conducts consultations with leading specialists from China, Türkiye and Germany.

Chinese experts play a crucial role in setting up new production lines at the company’s factories. Additionally, they provide comprehensive training to local staff, ensuring efficient operation of the latest equipment.

The dynamic transformation of Turkmenistan’s agro-industrial complex presents exciting new opportunities. Recognizing this shift, Türkmen Senagat, in collaboration with foreign partners, plans to install a production line dedicated to geomembranes. These materials serve as insulating component in the construction of diverse reservoirs and foundations. ///nCa, 9 July 2024 (based on the materials published by the newspaper “Neutral Turkmenistan”)