In Farab, Lebap province of Turkmenistan, there is a unique production facility — a workshop for recycling used plastic containers. This company not only solves an important environmental problem, but also produces high-quality products that are in demand abroad, as reported by the newspaper “Neutral Turkmenistan.”

With the spread of plastic containers worldwide, the problem of their disposal has emerged, as natural decomposition takes years. Consumption of such containers remains consistently high and, as a result, waste is growing, including in Turkmenistan. That is why the issue of disposal is particularly acute.

The history of the enterprise began with the initiative of local entrepreneur Rozumbay Rejepov. Initially, his business model was simple: collected plastic containers were crushed on a special machine, and the resulting raw materials were sold abroad. However, in 2019, when trade relations with partners were suspended due to the global pandemic, the entrepreneur decided to revise his strategy.

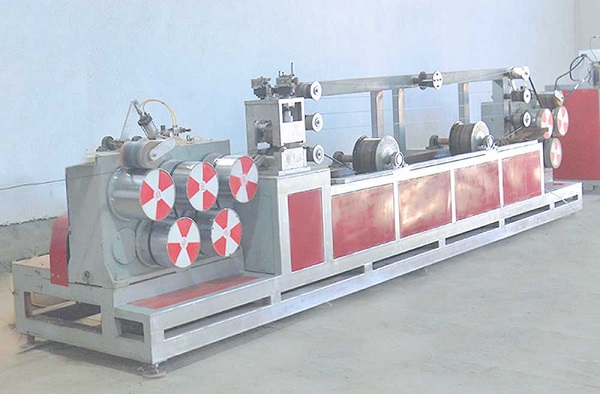

Rejepov decided to process the raw materials on-site and sell finished products. For this purpose, special equipment for the production of plastic strapping was purchased from China. In April of last year, the workshop produced its first products.

“Support from the government has stimulated us to engage in production activities. If earlier entrepreneurs were mainly involved in trade and service sectors, now their number in the manufacturing sector is growing every year. Products manufactured by small enterprises replace many types of imports, and surpluses are exported,” says Rejepov.

To date, the bulk of the products produced in Rejepov’s workshop are exported. Polyester ribbons with the label “Made in Turkmenistan” are supplied to Türkiye, Georgia and Uzbekistan. Due to their high strength and corrosion resistance, these tapes are widely used for wrapping large packages of household goods, furniture and building materials.

The production is focused on the needs of consumers: they produce tapes with a width of 12 to 22 millimeters and a thickness of 0.6 to 2 millimeters.

The workshop is capable of processing from 200 to 250 kilograms of plastic per hour, which is about five tons of raw materials per day.

“We collect raw materials from the population. The purchasing power of the population is growing every year. At the same time, the need for various products, including beverages, some of which are sold in plastic containers, is growing. Now, no family celebration goes without such drinks; they are consumed in large quantities all year round. As a result, waste accumulates, which serves as raw material for our production,” says Rustam Rejepov.

The entrepreneur emphasizes the double benefit of his business: “By recycling plastic waste, we not only prevent environmental pollution but also make a profit.”

Thus, the plastic processing workshop in Farab is an example of a successful combination of environmental responsibility and business initiative, which fully corresponds to Turkmenistan’s state policy on developing environmentally safe productions and supporting private entrepreneurship. ///nCa, 4 March 2025